CWaste Plastic Tyre Pyrolysis Machine for Sale Biomass Pyrolysis

Plant

1. Introduction of Carbonizing Retort Machines Biomass Charcoal

Retort machines retort:

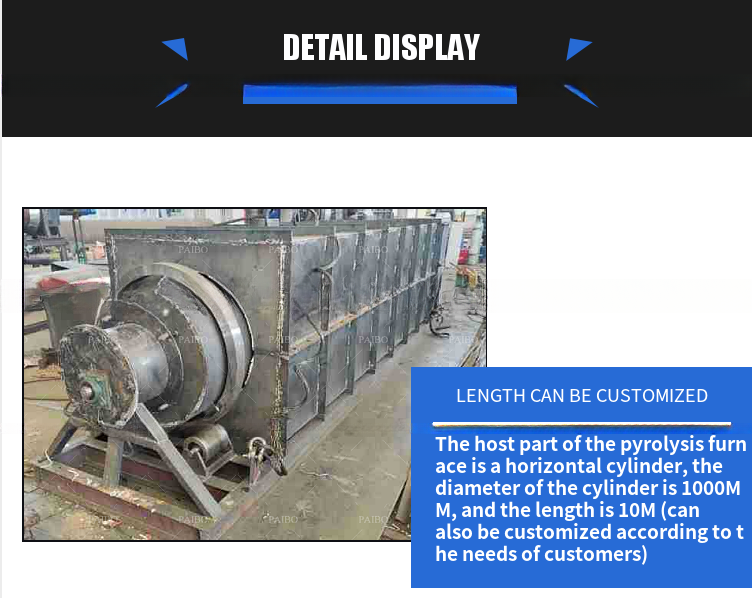

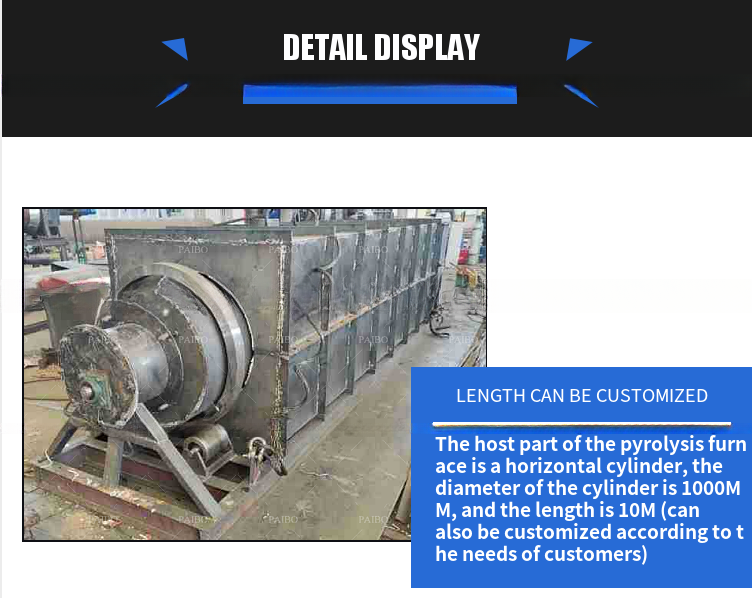

Charcoal carbonizing furnace is a kind of new air flow type

carbonization stove, can also be called as charcoal carbonization

stove. It is used to make charcoal from wood and all kinds of

biomass. It adopts new advanced hot air carbonizing technology,

greatly improves the carbonization rate to 99%, compared with the

carbonization rate 80% of traditional carbonization stove! Its

charcoal making time is short .This kind stove is safe and easy to

operate,the charcoal made from the carbonizing furnace can be the

material of activated carbon. thus it is very famous among many

industries like charcoal making industry and boiler industry!

2. Characteristics of Carbonizing Retort Machines Biomass Charcoal

Retort machines biochar pyrolysis retort :

New type of carbonization equipment, production higher than general

furnace, fast speed, high carbon, simple operation with smoke purification device, can store tar, no leakage, long

service life;

Suitable for wood, logs, mechanism charcoal, nut shell, bamboo,

etc, different shaps biomass raw material.

3. Advantages of Carbonizing Retort Machines Biomass Charcoal

Retort machines :

a. No polution: there are two reasons : the frog and the gas flow

will be recycle from the smoke recycle device and use for heating

the kiln again. We install a special device that can use the liquid

gas as the energy to heating the carbonization kiln, and it will

not produce any smoke.

b. Carbonize time more shorter: This type have three inner stove,

when one inner stove finished (6- 8hours ) , use the hoist tools

lift the inner stove out let it cooled naturally, at the same time,

lift the other one in , 3 inner stove can work continuously. 24

hours can carbonizing 3-4 inner stove.

c. Easy operate: One people can control 2-3set, but need the crane for

help; When one inner stove have been finished carbonization, use

the hoisting tools hoist the inner stove from the outer stove, then

let the inner stove natural cooling, at the same time, put another

inner stove into the outer stove, which will save a lot of cooling

time, so the productivity effect increase a lot.

- Thermometer : Measuring furnace temperature.

- Sealing cap:Seal to maintain the temperature inside the furnace, to ensure

into a good effect of carbonization.

- Combustion Chamber: Fire the furnace and to make the charcoal. There is the combustible

gas to produce and this gas can be sent to the bottom of the fire

mouth to let the machine heat.

- Carbonization Chamber:The raw materials are thermally decomposed in combustion chamber to

generate a large amount of acetic acid, methanol, wood tar and

other liquid products; also produced combustible gases such as

methane and ethylene.

- Smoke recovery system:The flammable gases are treated by flue gas purification, and are

returned to the carbonization machine for burning, providing heat

to the carbonization furnace, increasing the furnace temperature,

and generating carbon at high temperatures.

CARBONIZATION REQUIREMENTS

Biomass particles or e-waste with a particle size of less than 50mm

and a moisture content of less than 20% can be directly entered

into the first-type machine for carbonization.

For example, sawdust, coconut shells, fruit shells, palm shells,

etc. can be directly carbonized;

larger (50mm or more) raw materials, such as aluminum capacitors,

wires, waste clothes, wood branches, etc.,need to be shredded and

then carbonized;

if the moisture exceeds 30%, it needs to be dried in advance.

This product is a customized product, and the display price is for

reference only