Pulse Bag Dust Removal Machines Lithium Battery Crushing and

Sorting Environmental Protection Machines

RAW MATERIALS

The Lithium Ion Battery Recycling Machine is used for dismantling

and recycling the soft package battery, cellphone battery, shell

battery, cylindrical battery etc.

Different types of lithium batteries have different recycling

procedures.

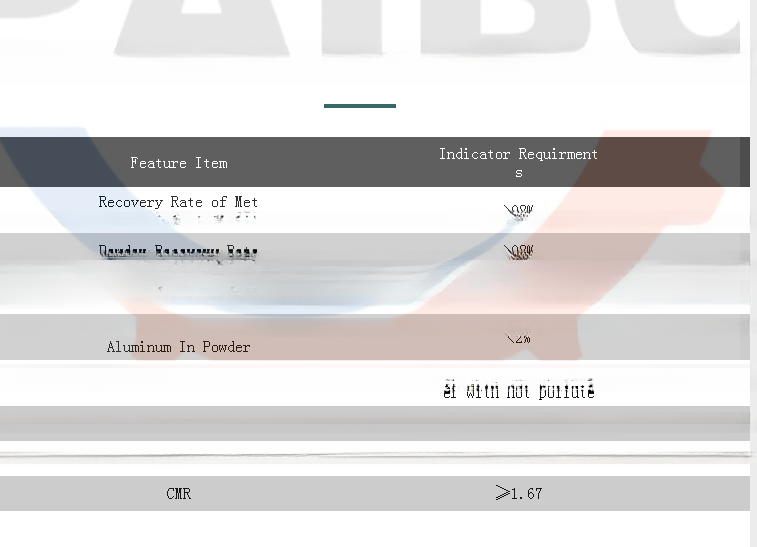

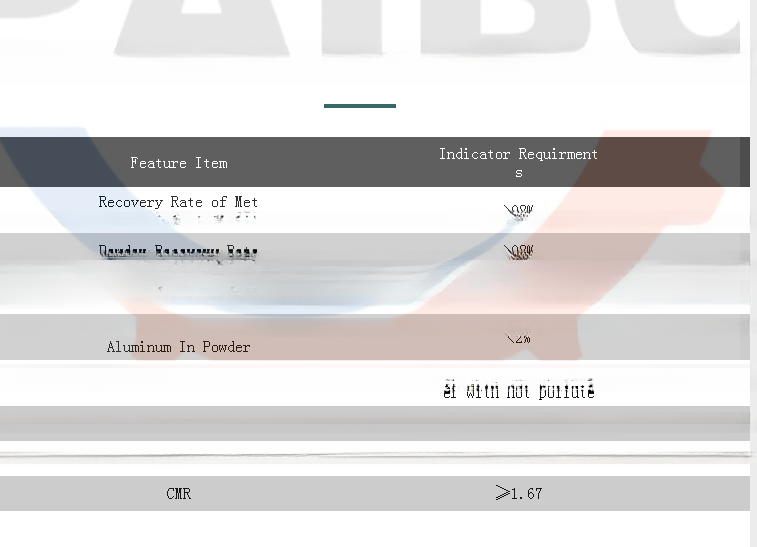

FEATURES OF LITHIUM BATTERY RECYCLING PLANT

1.Lithium battery recycling plant mainly adopts physical recycling

method, which has the characteristics of green and low carbon,

energy saving and environmental protection, and no secondary

pollution.

2.Taking economic and environmental benefits into account, both

valuable components can be utilized and harmful components can be

treated innocuously.

3.Lithium battery recycling machine was automatic, high recovery

efficiency, strong processing capacity, waste lithium battery

valuable components recovery rate of more than 98%.

LITHIUM BATTERY RECYCLING MACHINE STRUCTURE

The pretreatment process of lithium battery recycling machine

mainly comprises the following steps: after discharging the

recovered waste batteries, crushing, magnetic separation, air

separation, crushing, gravity separation, screening and other

processes are carried out by mechanical equipment.

The pretreatment process of waste lithium ion batteries mainly

comprises the following steps:

After discharging the recovered waste batteries,

Shredder: Shredded lithium batteries into smaller pieces.

Hammer crusher: For the secondary crushing of shredded materials.

Grinder: For the grinding of the crushed materials.

Separation machine: Separate the materials after being ground.

Collector: Collect and release the dust .

Pulse purifier (air cleaner): Clean all the dust produced during the operation of the

wholesystem.

Classifying screen:Screen the materials sorted by the separation machine,and screen

out oflarger metal materials.

Magnetic machine: Separate nickel from the metals.

Gravity separator:Separate those finer materials got from the screening machine and

separatethe metal completely.

High-pressure blower: Keep the whole system in a negative state so as to collect the

materialsand purity the air .

1.Lithium battery recycling plant mainly adopts physical recycling

method, which has the characteristics of green and low carbon,

energy saving and environmental protection, and no secondary

pollution.

2.Taking economic and environmental benefits into account, both

valuable components can be utilized and harmful components can be

treated innocuously.

3.Lithium battery recycling machine was automatic, high recovery

efficiency, strong processing capacity, waste lithium battery

valuable components recovery rate of more than 98%.

The pretreatment process of lithium battery recycling machine

mainly comprises the following steps: after discharging the

recovered waste batteries, crushing, magnetic separation, air

separation, crushing, gravity separation, screening and other

processes are carried out by mechanical equipment.

Our Services

How to packing of our machine:

1.Waterproof packing with the international export standard by

20ft, 40ft, 40hp container.

2. Equipment Fittings, Electric Motor and Power Cabinet will be

packed in Wooden Case or Iron Box. Other Equipment will be packed

by Color-Stripes Plastic Cloth.

3. Or as per customer's requirements.

Package

About Packing, for small size or single machine, we can offer free

fumigation wooden case with steel frame, it not only can protect

machine from damage, but also avoid checking when exporting.

For multiple machines or production line, it's better to loaded in

standard container 20GP, 40GP, 40HQ, unually it needs wrapped with

plasitc firstly, then loaded in container.

We can offer EXW, FOB and CIF terms.

EXW: You arrange the shipping details from our factory to your port

by yourself.

FOB: We arrange freight transport to Qingdao, Shanghai or other

ports of China, then you arrange the shipping details from China

port to your country port.

CIF: We arrange all shipping details to your country port, and

ensure machines smooth arrival.